-

We invite you to the exhibition GLASSTEC 2024 DÜSSELDORF

We invite you to the exhibition GLASSTEC 2024 DÜSSELDORF

on 22/10/2024 - 25/10 .2024 | Hall 12, stand F-70Silvering solutions for glass surfaces -

We invite you to the exhibition GLASSTEC 2024 DÜSSELDORF

We invite you to the exhibition GLASSTEC 2024 DÜSSELDORF

on 22/10/2024 - 25/10 .2024 | Hall 12, stand F-70Silvering solutions for glass surfaces -

We invite you to the exhibition GLASSTEC 2024 DÜSSELDORF

We invite you to the exhibition GLASSTEC 2024 DÜSSELDORF

on 22/10/2024 - 25/10 .2024 | Hall 12, stand F-70Silvering solutions for glass surfaces

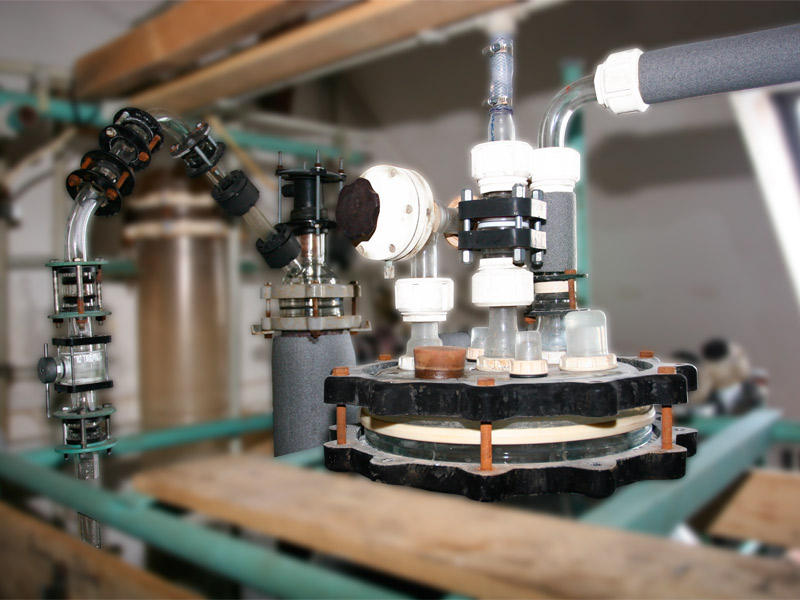

Stainless steel reactors make it possible to mix 15,000 liters of reducing solution in one batch.

Stainless steel reactors make it possible to mix 15,000 liters of reducing solution in one batch.